Summary:How to Choose a Ball Bearing

In order to make a Ball Bearing, the material used must be hard enough to withstand the lo...

How to Choose a Ball Bearing

In order to make a Ball Bearing, the material used must be hard enough to withstand the load. There are two main types of material, silicon nitride and bearing steel. Silicon nitride is low density and works well in high temperatures, but is not as strong as bearing steel or porcelain. Both types of material have different wear properties. Silicon nitride tends to wear out easily and produces debris. Silicon nitride is also more prone to tearing than steel and glass.

When choosing a Ball Bearing, you must first determine what the application will be. You need to consider the size, lubricant, and other factors, such as the presence of corrosive agents and stray electrical currents. Then, you can choose the right size and type. However, this is a complicated process. To avoid miscalculation, it is important to choose the proper type of bearing for your application. Listed below are some tips for choosing the right type of ball bearing.

A Conrad-style Ball Bearing can be truncated. When the outer ring ID is large enough, the inner ring is too small. The result is an oval shape, which increases the bearing's stresses. This phenomenon is known as contact ellipse truncation, and invalidates many general rules of thumb. Other construction styles can reduce the outer ring ID and increase the inner ring OD.

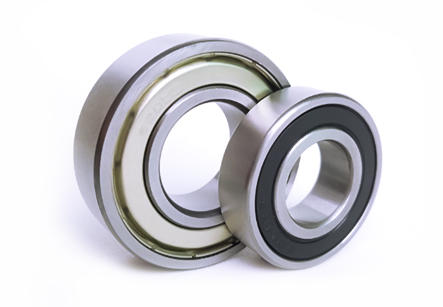

A Ball Bearing is the most common type of mechanical bearing and can handle small amounts of weight. The two races of a Ball Bearing contain balls that are sized to move freely between them and make contact with each other. A cage around the balls also helps retain the grease within the bearing. Ball bearings are available in different types, including metric and imperial sizes. The ball bearing is one of the most common types of mechanical bearing, and it is often used to minimize the friction.

The purpose of a Ball Bearing is to reduce friction in a rotating axis. The ball bearing uses two races, one stationary and one attached to a rotating assembly, such as a shaft or hub. These races allow the balls to rotate and reduce the friction. Friction is one of the most common causes of wear, and the precision of internal geometry can reduce friction. Friction is also influenced by speed of rotation, lubrication, and load.

While steel is commonly used in a Ball Bearing, it has a low load capacity for its size. High load capacity can be achieved with a combination of ceramic balls and steel rings. Ceramic balls are more durable than steel, but are also stiffer than metal. Therefore, a Ceramic hybrid Ball Bearing is a high performance alternative for applications where weight is of utmost importance. In addition to steel, a Ball Bearing can be made from a variety of materials, including metal, polymer, and a combination of both.

A Ball Bearing with angular contact uses axially asymmetric races. The axial load passes through the bearing in a straight line, while the radial load follows an oblique path and acts to separate the races axially. An Angular contact Ball Bearing's contact angles are the same on both the outer and inner race. Angular contact ball bearings are most common in handpieces, machinery, and vehicles, where rigid axial guidance is essential.

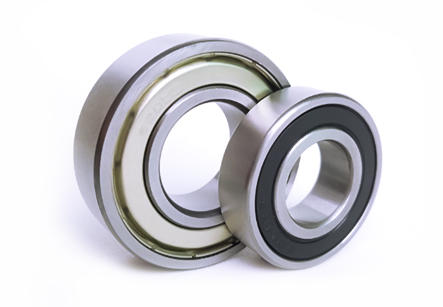

| Inside Diameter (mm): |

35 |

| Outside Diameter (mm): |

62 |

| Width (mm): |

9 |

| Rows Of Balls: |

single row |

| Internal Clearance: |

CN (Standard) |

| Slot & Snap Ring: |

no |

| Ring Material: |

Chrome Steel |

| Flange: |

no |

| Rolling Element Material: |

Chrome Steel |

| Seal: |

ZZ |

| Cage Material: |

Sheet Steel |

| Full Complement Ball Set: |

no |

| Product weight: |

0,002Kg |